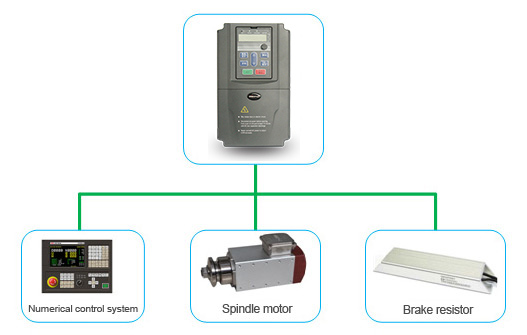

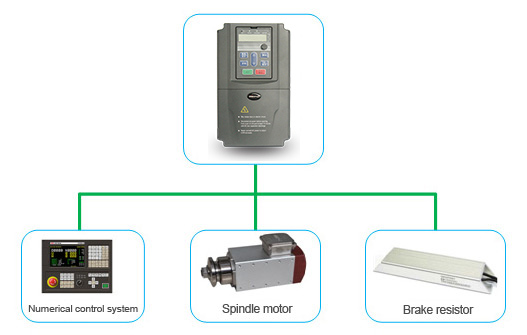

CNC is the main equipment of the modern mechanic manufacturing. It combines the machine tools, motor, computer, sensor and auto control, which can complete complicated, precise, small quantity and various parts cutting and processing task. The principle axis motion is the main source of power, including positive&negative rotation, start-stop, stepless speed regulation.

■ Wide range of speed adjustment and high torque output

■ Quick start-stop and precise stop control

■ Avoids mechanical resonance

■ Speed stability and prevent defective products

The CNC program is written based on the products. First pre-set the processing speed then output 4-20mA analog signal to VFD to control the speed of principle axis.

The VFD can get the accurate motor parameters through self-learning. Start the vector control to increase start torque and improve the system response speed and control performance. Braking function can consume excess energy to avoid over pressure stall and realize the quick start-stop. Built-in Modbus protocol RS485 function can communicate with upper machine, realize automation control, receive or output 0-100kHz pulse signal and be compatible with active transducer.